Gelest provides chemistries and deposition technologies for microparticle modifications. The surface of microparticles can be altered by silane surface treatments. The silane reacts onto the surface of the particle, leaving a desired organic functionality that can dramatically enhance particles properties such as:

- color

- polarity

- adhesion

- dispersion

- rheological behavior

- photo, chemical, and thermal stability

- moisture and corrosion resistance

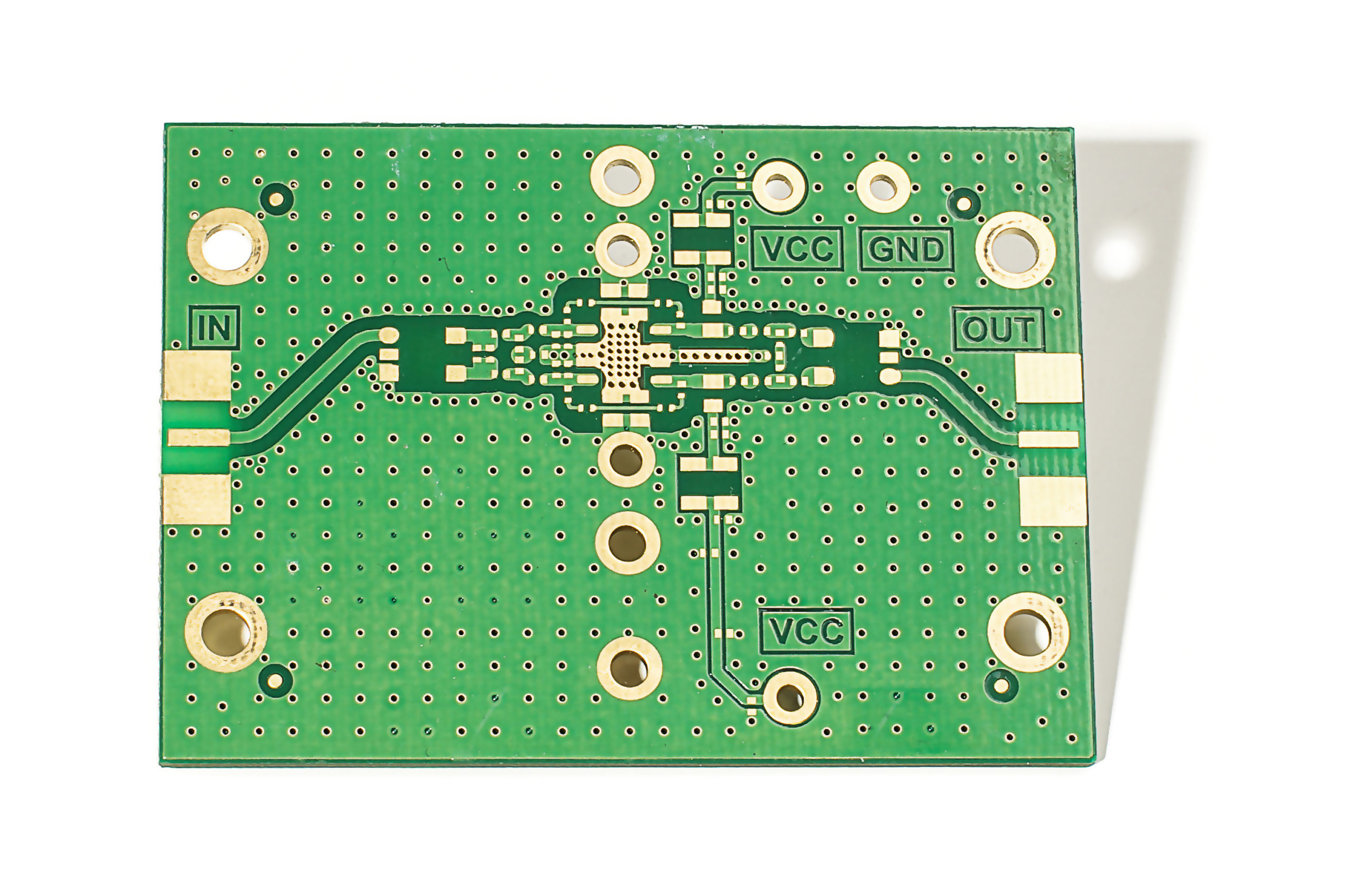

- mechanical and electrical properties

Example: microparticle treated with a linear alkylsilane (SIO6713.0, SIO6715.5, SIO6715.0) displays hydrophobic behavior

Example: microparticles treated with embedded PEG silanes (SIT8186.3) display improved dispersion with lower viscosity

A range of silica structures from 20 nm to 1 micron have been modified with silanes to reduce hydroxyl content allowing improved dispersion. Other versions have monolayers with isolated secondary amine functionality, providing controlled interactions with resins. Systems that maintain low levels of hydroxyls have improved electrical properties. Introduction of low levels of secondary amines impart improved mechanical properties particularly in high humidity environments.

Silicone dioxide, amorphous – SIS6960.0

Hexamethyldisilazane-treated silicone dioxide, amorphous – SIS6962.0. 3% carbon content.

Hexamethyldisilazane-treated silicone dioxide, amorphous – SIS6962.1M30. 2-3% carbon content.

Cyclic azasilane- / Hexamethyldisilazane-treated silicone dioxide, amorphous – SIS6962.1N30. 4-7% carbon content.

Modifying surface chemistry of pigments and powders provides robust, permanently modified behavior, expanding formulation latitude in personal care. Gelest has the unique ability to synthesize specialty silanes and silicones and employ these materials as reactive surface treatments. See our Personal Care surface-treated products here.

The functions of surface treatment in cosmetic formulations include:

- Improved skin feel

- Improved wetting

- Uniform color development

- Maximization of attainable pigment load

- Reduction in the amount of energy and time required for dispersion

- Passivation of the pigment surface to reduce physical and chemical interaction with the vehicle

These siliceous surface treatments can show:

- Lubricious tactile effect

- Precise surface energy control

- Water repellency – hydrophobicity

- Water dispersibility – hydrophilicity

- Dispersion and rheological control

- Stability throughout the range of physiological pH

- Oil repellency – oleophobicity

- Stable Interaction with siloxane, organic and aqueous phases –lipophilicity

Recommended Applications:

- Pencils

- Eyeliners

- Mascaras

- Sunscreens

- Foundations

- Loose powders

- Pressed powders

- Powdercream products

Gelest has worked with a variety of particles including natural and synthetic siliceous particles, natural and synthetic non-siliceous particles, and specialty particles such as metallic, fluorescent, luminescent, and phosphorescent. If interested in a custom surface treatment, please contact our Technical Service department. We are capable of handling a wide range of materials with special process considerations including: inert atmospheres, highly flammable and corrosive treatments, as well as thermal and vacuum drying.

Potential applications for microparticle surface treatments:

- Glass

- Energy

- Textiles

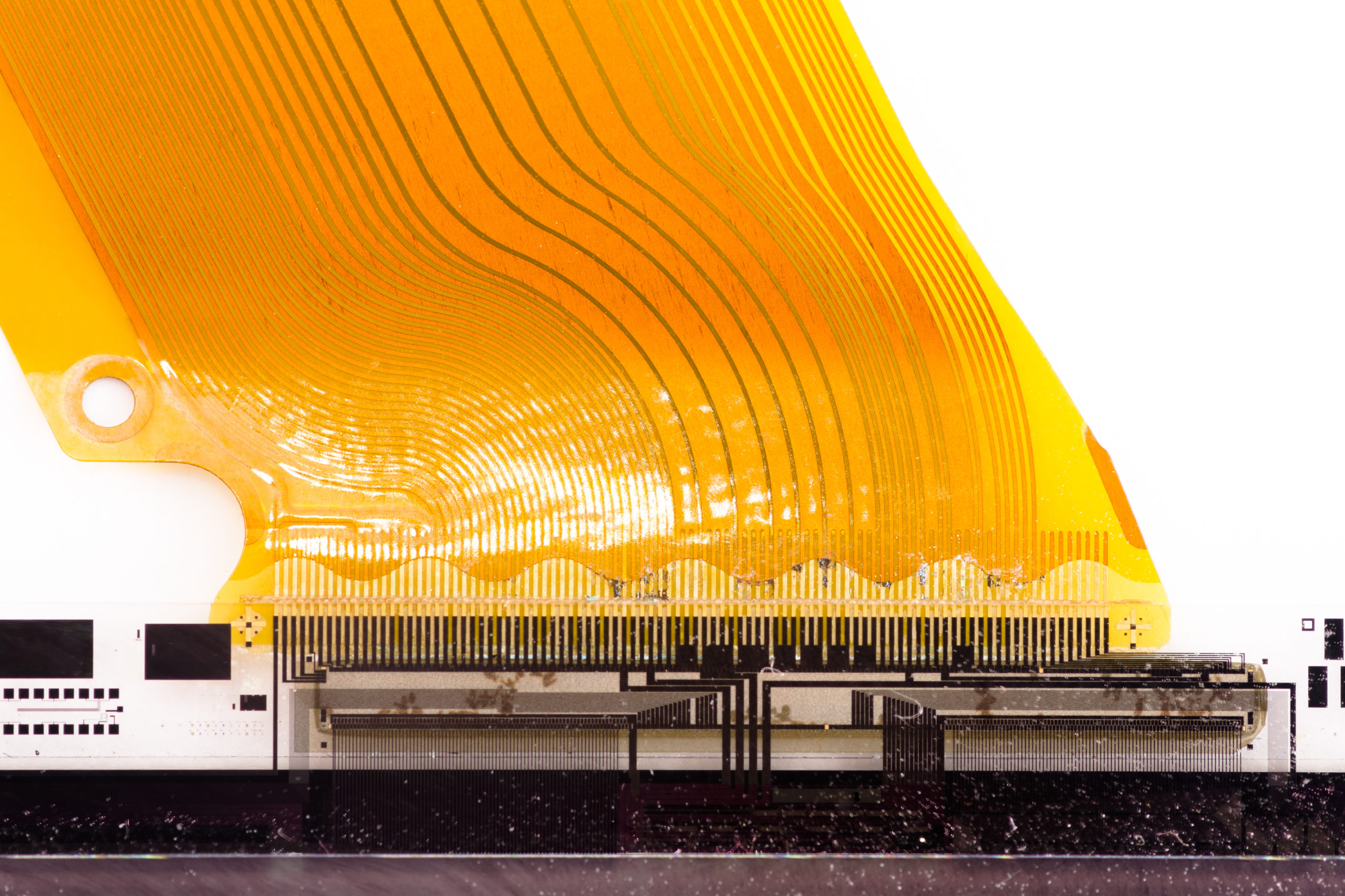

- Displays

- Ceramics

- Digital inks

- Thermosets

- Biomaterials

- Printing inks

- Quantum dots

- Semiconductor

- Thermoplastics

- Chromatography

- Nanocomposites

- Imaging and printing

- Advanced composites

- Optics and optoelectronics