Silane surface modification can be influenced by:

- Concentration of surface hydroxyl groups

- Type of surface hydroxyl groups

- Hydrolytic stability of the bond formed

- Physical dimensions of the substrate/substrate features

Substrates vary widely, containing different concentrations and types of hydroxyl groups on the surface. An increased number of accessible hydroxyl groups on the surface is likely to lead to a better surface modification.

Silanes with three alkoxy groups (trialkoxysilanes) are the usual starting point for substrate modification. These materials tend to deposit as polymeric films, affecting total coverage and maximizing the introduction of organic functionality. They are the primary materials used in composites, adhesives, sealants, and coatings. Residual (non-condensed) hydroxyl groups from alkoxysilanes can also interfere in activity. Monoalkoxysilanes can be used for nano-featured substrates since deposition is limited to a monolayer.

If the bond between the silane and the substrate is poor or exposed to an aqueous environment, a dipodal silane can be incorporated to improve stability. These dipodals form tighter networks and may offer up to 105 times greater hydrolysis resistance making them particularly appropriate for primer applications.

| Average Particle Size (μm) | Amount of Silane (minimum monolayer coverage) |

|---|---|

| < 1 | 1.5% or greater |

| 1-10 | 1.00% |

| 10-20 | 0.75% |

| > 100 | 0.1% or less |

While the contact angle of water on a substrate is a good indicator of the relative hydrophobicity or hydrophilicity of a substrate, it is not a good indicator for the wettability of the substrate by other liquids. The contact angle is given by Young’s equation: γsν – γsl = γlν • cosθe where γsl = interfacial surface tension, γlν = surface tension of liquid.

Critical surface tension is associated with the wettability or release properties of a solid. It serves as a better predictor of the behavior of a solid with a range of liquids. Liquids with a surface tension below the critical surface tension (γc) of a substrate will wet the surface, i.e., show a contact angle of 0 (cosθe = 1). The critical surface tension is unique for any solid and is determined by plotting the cosine of the contact angles of liquids of different surface tensions and extrapolating to 1.

Hydrophilic behavior is generally observed by surfaces with critical surface tensions greater than 45 dynes/cm. As the critical surface tension increases, the expected decrease in contact angle is accompanied with stronger adsorptive behavior and with increased exotherms.

Hydrophobic behavior is generally observed by surfaces with critical surface tensions less than 35 dynes/cm. At first, the decrease in critical surface tension is associated with oleophilic behavior, i.e. the wetting of the surfaces by hydrocarbon oils. As the critical surface tensions decrease below 20 dynes/cm, the surfaces resist wetting by hydrocarbon oils and are considered oleophobic as well as hydrophobic.

In the reinforcement of thermosets and thermoplastics with glass fibers, one approach for optimizing reinforcement is to match the critical surface tension of the silylated glass surface to the surface tension of the polymer in its melt or uncured condition. This has been most helpful in resins with no obvious functionality such as polyethylene and polystyrene. Silane treatment has allowed control of thixotropic activity of silica and clays in paint and coating applications. Immobilization of cellular organelles, including mitochondria, chloroplasts, and microsomes, has been effected by treating silica with alkylsilanes of C8 or greater substitution.

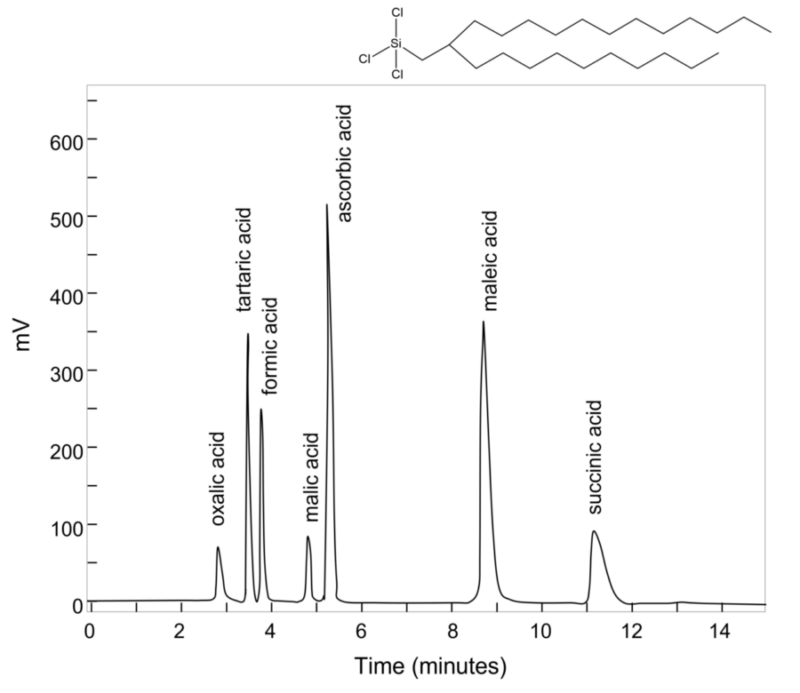

Octadecyl, cyanopropyl and branched tricocyl silanes provide bonded phases for liquid chromatography. Reverse phase thin-layer chromatography can be accomplished by treating plates with dodecyltrichlorosilane.

The interphase can also impose orientation of the bulk phase. In liquid crystal displays, clarity and permanence of image are enhanced if the display can be oriented parallel or perpendicular to the substrate. The use of surfaces treated with SIO6620.0 (perpendicular) or SIM6500.0 (parallel) has eliminated micromachining operations. The oriented crystalline domains often observed in reinforced nylons have also been attributed to orientation effects of the silane in the interphase.

A Self-Assembled Monolayer (SAM) is a one molecule thick layer of material that bonds to a surface in an ordered way as a result of physical or chemical forces during a deposition process. Silanes can form SAMs by solution or vapor phase deposition processes. Most commonly, chlorosilanes or alkoxysilanes are used and once deposition occurs a chemical (oxane) bond forms with the surface rendering a permanent modification of the substrate. Applications for SAMs include micro-contact printing, soft lithography, dip-pen nanolithography, anti-stiction coatings and orientation layers involved in nanofabrication of MEMs, fluidic microassemblies, semiconductor sensors and memory devices.

Common long chain alkyl silanes used in the formation of SAMs are simple hydrocarbon, fluoroalkyl and endgroup substituted silanes. Silanes with one hydrolyzable group maintain interphase structure after deposition by forming a single oxane bond with the substrate. Silanes with three hydrolyzable groups form siloxane (silsesquioxane) polymers after deposition, bonding both with each other as well as the substrate. For non-oxide metal substrates, silyl hydrides may be used, reacting with the substrate by a dehydrogenative coupling.

The perpendicular orientation of silanes with C10 or greater length can be utilized in micro-contact printing and other soft lithography methods. Here the silane may effect a simple differential adsorption, or if functionalized have a direct sensor effect.

In contrast with silanes utilized as coupling agents in adhesive applications, silanes can be used to modify the surface energy or wettability of substrates. More information can be found in the Hydrophobicity, Hydrophilicity, and Silane Surface Modification section.

Coupling agents find their largest application in the area of increased adhesion to polymers. In this context, only silanes that form covalent bonds directly to the polymer will be considered. The covalent bond may be formed by reaction with the finished polymer or copolymerized with the monomer. Thermoplastic bonding is achieved through both routes although principally the former and thermosets are almost entirely limited to the latter. The mechanism and performance of silane coupling agents is best discussed with reference to specific systems. The most important substrate is E-type fiberglass, which has 6-15 silanol groups per mμ2.

Acrylates, methacrylates, and unsaturated polyesters easily undergo free-radical polymerization and can therefore be modified by copolymerization with silanes that have unsaturated organic substitution. The usual coupling agents for thermoset polyesters undergo radical copolymerization in such systems. These resins, usually of loosely defined structure, are often mixed with a second monomer like styrene to reduce viscosity. The silane monomer should match the reactivity of the styrene rather than the maleate portion of the polyester for better reinforcement. Methacrylyl- and styryl-functional silanes undergo addition much more readily than vinylsilanes. Vinyl-functional silanes mismatch the reactionary parameters of most unsaturated polyesters but can be used in direct high pressure polymerization with olefins such as ethylene, propylene, and dienes.

Thermoset urethanes can be effectively coupled with two types of silanes. The first type, including isocyanate-functional silanes, may be used to treat the filler directly or integrally blended with the diisocyanate (TDI, MDI, etc.) prior to cure. Amine- and alkanolamine-functional silanes, on the other hand, are blended with the polyol rather than the diisocyanate. Alkanolamine-functional silanes react with the isocyanate to form urethane linkages, while amine silanes react with the isocyanates to yield urea linkages. A typical application for coupled urethane systems is to improve bond strength with sand in abrasion-resistant, sand-filled flooring resins.

Secondary aminosilanes have the general ability to convert isocyanate-functional urethane prepolymers to systems that crosslink in the presence of water and a tin catalyst. The preferred aminosilanes are secondary amines containing methyl, ethyl, or butyl substitutions on nitrogen.

Epoxycyclohexyl- and glycidoxy-functional silanes are used to pretreat the filler or to blend with the glycidylbisphenol-A ether. Amine-functional silanes can likewise be used to pretreat the filler or to blend with the hardener portion. Treating the fillers in epoxy adhesives improves their dispersibility and increases the mechanical properties of the cured resin. A large application area is glass cloth-reinforced epoxy laminates and prepregs in aerospace and electrical printed circuit board applications.

Phenolic resins are divided into base-catalyzed singlestep resins called resols or acid-catalyzed two-step systems called novolaks. Although foundry and molds are formulated with resols such as aminopropylmethyldialkoxysilanes, the commercial utilization of silanes in phenolic resins is largely limited to novolak/glass fabric laminates and molding compounds. The phenolic hydroxyl group of the resins readily reacts with the oxirane ring of epoxy silanes to form phenyl ether linkages. When phenolic resins are compounded with rubbers (as in the case with nitrile/phenolic or vinyl butyral/phenolic adhesives) or impact-resistant molding compounds, additional silanes—particularly mercapto-functional silanes—have been found to impart greater bond strength than silanes that couple to the phenolic portion.

Thermoplastics provide a greater challenge in promoting adhesion through silane coupling agents than thermosets. The silanes must react with the polymer and not the monomeric precursors, which not only limits avenues for coupling, but also presents additional problems in rheology and thermal properties during composite formulation. Moreover mechanical requirements here are stringently determined. Polymers that contain regular sites for covalent reactivity either in the backbone or in a pendant group include:

- polydienes,

- polyvinylchloride,

- polyphenylene sulfide,

- acrylic homopolymers,

- maleic anhydride,

- acrylic,

- vinyl acetate,

- diene-containing copolymers, and

- halogen- or chlorosulfonyl-modified homopolymers.

A surprising number of these are coupled by aminoalkylsilanes. Chlorinated polymers readily form quaternary compounds while the carboxylate and sulfonate groups form amides and sulfonamides under process conditions. At elevated temperatures, the amines add across many double bonds although mercaptoalkylsilanes are the preferred coupling agents. The most widely used coupling agents, aminoalkylsilanes, are the most economical but are not necessarily the best. Epoxysilanes, for example, are successfully used with acrylic acid and maleic acid copolymers.

Scanning electron micrograph at a broken gear tooth from: a) a non-coupled glass fiber/acetal composite. Cleavage occurred between fibers. b) an aminosilane-coupled glass fiber/nylon 6/6 composite. Fibers have broken as well as the matrix.

The group of polymers that most closely approaches theoretical limits of composite strength does not appear to contain regular opportunities for covalent bond formation to substrate. Most of the condensation polymers including polyamides, polyesters, polycarbonates, and polysulfones are in this group. Adhesion is promoted by introducing high energy groups and hydrogen bond potential in the interphase area or by taking advantage of the relatively low molecular weights of these polymers, which results in a significant opportunity for end-group reactions. Aminoalkylsilanes, chloroalkylsilanes, and isocyanatosilanes are the usual candidates for coupling to these resins. These silanes improve the mechanical strength of the thermoplastics, allowing them to replace the cast metals in such typical uses as gears, connectors, and bobbins.

The polyolefins and polyethers present no direct opportunity for covalent coupling. Until recently, the principal approach for composite formulation was to match the surface energy of the filler surface—by treating it with an alkyl-substituted silane—with that of the polymer. For optimum reinforcement, preferred resins should be of high molecular weight, linear, and have low melt viscosity. Approaches to improved composite strength have been through compatibility with long-chain alkylsilanes or aminosilanes. It is more effective to couple with vinyl or methacryloxy groups, particularly if additional coupling sites are created in the resin by addition of peroxides. Dicumyl peroxide and bis(t-butylperoxy) compounds at levels of 0.15% to 0.25% have been introduced into polyethylene compounded with vinylsilane-treated glass fibers for structural composites or vinylsilane-treated clay for wire insulation. 50% increases in tensile and flexural properties have been observed in both cases when compared to the same silane systems without peroxides.

Another approach for coupling polypropylene and polyethylene is through silylsulfonylazides. Unlike azide bound to silicon, sulfonyl azides decompose above 150 °C to form a molecule of nitrogen and a reactive nitrene that is capable of insertion into carbon-hydrogen bonds to form sulfonamides, into carbon-carbon double bonds to form triazoles, and into aromatic bonds to form sulfonamides. Fillers are treated first with the silane and then are fluxed rapidly with polymer melt.

One of the more innovative ways of modifying the surfaces of polyolefins is to apply a multipodal oligomeric coupling agent, such as SSP-055, SSP-056, SSP-058, or SSP-255. Such oligomers provide better adhesion to polyolefins and still have the linking effect of silane dipodal chemistry in attaching to surfaces. The olefin-based backbones provide great compatibility with all hydrophobic olefins as well as with elastomers of various types. Finally, an oxygen plasma treatment prior to applying silane coupling agents produces hydroxyl radicals on a polyolefin surface. These hydroxyl radicals provide good linkage sites for any silane coupling agent to link onto the polyolefin surface, which opens a larger range of applicable silanes.

An important factor in controlling the effectiveness and properties of a coupled system is the linker between the organic functionality and the silicon atom. The linker length imposes a number of physical property and reactivity limitations. The desirability of maintaining the reactive centers close to the substrate are most important in sensor applications, heterogeneous catalysis, fluorescent materials, and composite systems in which the interfacing components are closely matched in modulus and coefficient of thermal expansion.

On the other hand, inorganic surfaces can impose enormous steric constraints on the accessibility of organic functional groups in close proximity. If the linker length is long, the functional group has greater mobility and can extend further from the inorganic substrate. This is important if the functional group is expected to react with a single component in a multicomponent organic or aqueous phase found in homogeneous and phase transfer catalysis, biological diagnostics, or liquid chromatography. Extended linker length is also important in oriented applications such as self-assembled monolayers (SAMs). The typical linker length is three carbon atoms, a consequence of the fact that the propyl group is synthetically accessible and has good thermal stability.